Why do you need Health and Safety Management?

You have a legal requirement under UK law to manage the health, safety, welfare and wellbeing of your employees, and people affected by the operations of your business. You need to be aware of Health and Safety legislation, that is relevant to your business. You have a legal obligation to draw up a Health and Safety Policy and arrangements. This document sets out what you will do to manage the health and safety within your business. The HSMS ensures you have the tools, tests, documents, and training to make the arrangements effective. It will ensure you and your staff are working as a team, towards a common goal. Key requirements will ensure you are legally compliant and will reduce accidents or potential illness help increase the efficiency of your workforce providing a positive Health and Safety Culture.

Why is Health & Safety Management Important?

You have a 'duty of care' to your employees and those affected by your operations. If you breach that duty you are putting people at risk from harm, through injury, sickness or even death. If you do not take measures to fullfil your duty of care, you are exposing the company and potentially yourself to hefty fines and possible imprisonment as well as damage to you company's reputation and destroying lives.

A Health and Safety Management System will help you ensure you have an effective level of health and safety control measures in place to protect workers and others. These controls should be tried and tested and designed to identify hazards, eliminate where possible risk and ensure you remain legally compliant. But most importantly you will be protecting the lives of your workers. Did you know that In UK, Health and Safety is the one area of law where you are guilty unless you can prove yourself to be innocent.

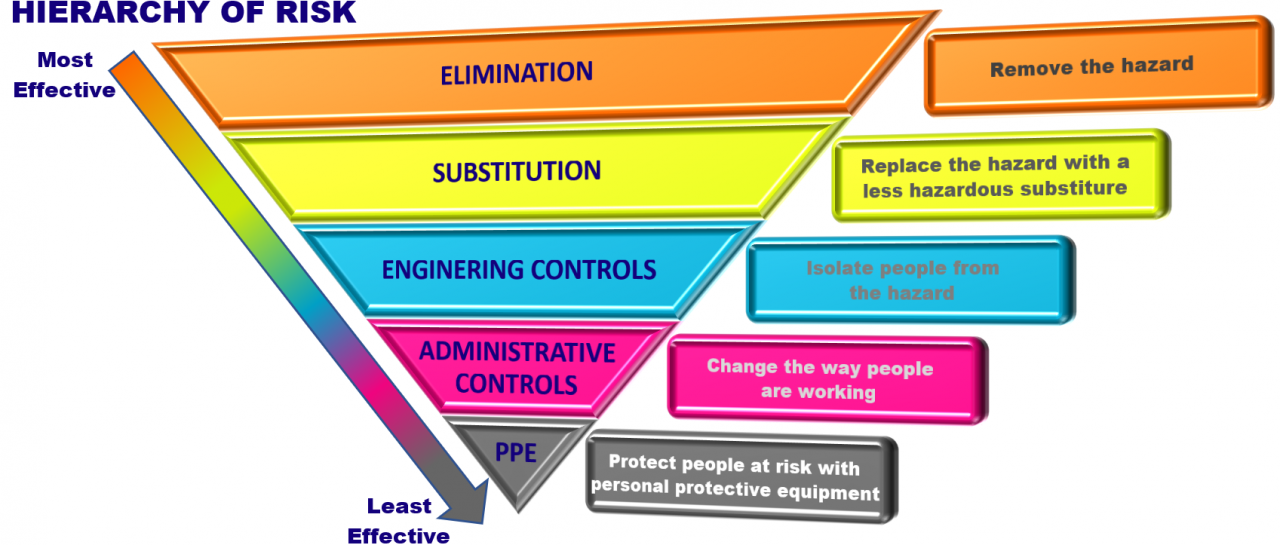

Hierarchy of Risk

The Management of Health and Safety at Work Regulations 1999 section 3 details legal requirements for Risk assessments with Schedule 1 listing the General Principles of Protection which have been translated into the common terminology of the 'Hierarchy of Risk':

What are my Health and Safety Legal Obligations?

There is a large amount of legislation in the UK in respect to Health and Safety. The overriding Act being the Health and Safety at Work Act 1974 all legislation is accessible free of charge online at https://www.legislation.gov.uk.

The Health and Safety Executive (HSE) have a vast amount of literature available online. These documents are designed to help you understand the requirements of UK law, your legal obligations and best practice. They can be found at https://www.hse.gov.uk. Key publications have the status of Approved Codes of Practice (ACOPS) and focus on specific UK regulations, cutting through the legal jargon and explaining what implement and how to ensure you meet your legal obligations.

What are the areas a HSMS must control?

All control measures should be specific to your business and focused on the control of hazards and elimination of risk. The 7 points below cover top control measures any company should consider as a minimum when considering the health, safety and wellbeing of staff:

Management of Risks

Risk is managed through identification of Hazards and assessing the associated risk using the Hierarchy of Risks as set out in Appendix 5 of the Health and Safety Work Act. The are some risk assessments that are mandatory for business and if you have 5 or more employees these need to be written down. These include but are not restricted to:

- Fire

- COVID 19

- Hand Arm Vibration (HAVs)

- Whole Body Vibration (WBV)

- Noise

- Fumes

- Control of Substances Hazardous to Health (COSHH)

- Electrical Safety

- Trips, Slips and Falls

- Manual Handling

- Working at Height

- Display Screen Equipment (DSE)

Safe Systems of Work (SSOW)

These are sometimes referred to as Safe Operational Procedures (SOPs). They are task specific and designed to instruct operators on how to complete the task safely and without danger to health.

Control of Substances Hazardous to Health (COSHH)

The Control of Substances Hazardous to Health 2002 (COSHH) is a UK law states you have a requirement to control the storage and use, dispose of hazardous substances and avoid explosive atmospheres under DSEARS 2002.

Accidents, Incidents, Near Misses and Dangerous Occurrences

Seeking to reduce any of these should be a top priority for any company and a legal duty. But did you know that in certain circumstances you have a legal obligation to report the to the Health and Safety Executive (HSE). Under RIDDOR - Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 there are strict criteria for managing and reporting and when this should be escalated to the HSE through their online portal https://www.hse.gov.uk/riddor/report.htm.

Statutory Testing of Work Equipment

The UK regulations for this area is The Provision and Use of Work Equipment Regulations 1998 (PUWER) and it covers work equipment and machinery within the workplace that is in everyday use. Its purpose is to keep people safe when equipment and machinery is used at work.

Statutory Testing of Lifting Equipment

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) ensure that all lifting equipment is used safely. If you have employees operating lifting equipment, then you are required to comply to these regulations.

Contractor Management

You may use contractors to help you complete your projects, or to carry out improvements on you premises. Did you know that whilst onsite you have the same duty of care for them as you do your own employees?